Automated test system improves product consistency of photon counters

Photek manufacture image intensifiers, ultrafast photomultipliers and photon counting equipment for use in research and scientific experiments. The products are used in exciting applications ranging from the detection of single photons, timing of light pulses with rise times as fast as 100ps, vacuum time of flight measurements, ultra-fast cameras capable of frame achieving frame rates of 1 billion frames per second and are currently supplying detectors for the Large Hadron Collider at CERN.

Photek also manufacture custom detectors for space applications some of which are in earth orbit and others on their way to Pluto! They are also involved in an EEC funded project BioLISME which aims to produce a biosensor capable of rapid detection of Listera

The requirement & Solution

Manufacturing of detectors takes place inside temperature-controlled vacuum process chambers using high voltage power supplies for conditioning components and high current DC power supplies necessary for photocathode deposition and driving of electron guns. The current produced by the photocathode is monitored throughout the manufacturing process using a highly accurate Picoammeter.

This original production process was previously carried out by an Engineer who manually controlled and logged voltages, measured current and operating temperature. He then made adjustments to voltages, currents and temperature over a 7 day period to produce the detector. This manual process was inconsistent and consequently resulted in significant variations in product quality or consistency.

Photek wanted an automated system to control the whole process in order to improve the consistency of manufacturing by removing human error and thereby improve product quality.

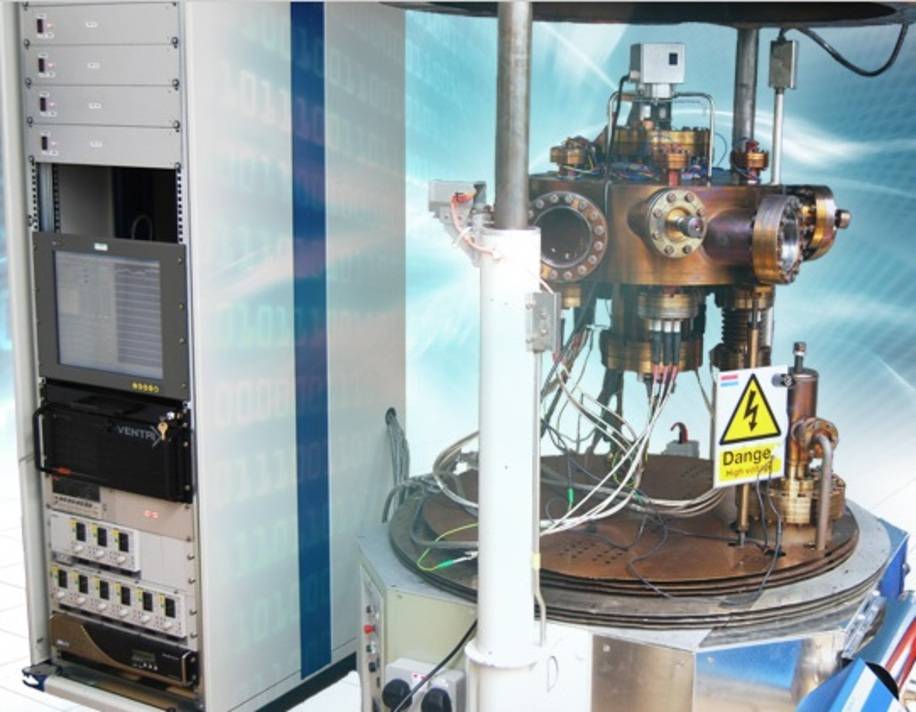

Amplicon supplied a rackmount test system with LCD touch screen comprising an industrial computer running Windows XP and LabVIEW, various data acquisition cards and a GPIB interface for connection to additional instrumentation; these were housed in a bespoke 39U rack cabinet.

The analogue output card was used to control custom made high voltage power supplies and an analogue input card monitored the outputs voltages and currents for precise control. Constant current power supplies and a Picoammeter were connected to the computer using the GPIB interface. The vacuum chamber is heated to specific temperatures during the manufacturing process and the switching of the heaters is controlled by a relay card. The temperature of the process chamber is monitored using a USB thermocouple interface. An uninterruptable power supply (UPS) was provided to ensure continuous operation in the event of a short power failure.

Results

Photek

The Amplicon test system does exactly what we wanted and has helped make a significant improvement to product consistency. With processes being operated 24 hours a day we have also been able to reduce the manufacturing cycle time thus allowing greater utilisation of equipment.

Martin Ingle - Photek

Why Amplicon?

Amplicon have a history of providing complex test systems. They have a UK based engineering, project management and configuration team who can design, build, and test complete systems.

Photek chose Amplicon because they were able to understand the technical requirements for the test system, support the product technically both pre and post-sales, and deliver the unit fully assembled and tested, ready for use by Photek.