Process Control

For many years Amplicon has been supplying the process control industry with innovative and technologically advanced products and systems.

We design and configure process control solutions, both simple and complex, across a broad range of industries such as Food & Beverage, Oil & Gas, Renewables, Electrical Power, Water/Waste Water and Transportation.

With the potential to reduce costs and improve efficiency, remote automation and monitoring technologies are becoming increasingly attractive options for consideration in today's industrial market.

We can offer remote I/O products with a variety of industry standards such as Modbus TCP/IP and Profibus-DP, network solutions with redundant communications, and industrial computers for SCADA and other software applications that can measure, analyse, control and automate to allow you to improve any process related operation.

Products

Amplicon has over 40 years’ experience in supplying process control and factory automation solutions.

Controllers

Amplicon has a comprehensive range of cost effective yet innovative controllers including PAC’s, Rackmount computers, Panel PC’s and Embedded PC’s that are specifically designed to cater for process control applications.

Serial I/O

Amplicon offers a wide range of multi-channel serial remote I/O products that are designed for any process signal travelling over an RS485 network. For applications that require a vast amount of different process signals the modular serial remote I/O will be the perfect solution.

Ethernet I/O

Our broad range of innovative remote Ethernet I/O products can handle any typical process signal, along with a variety of valuable features that allow process engineers to reduce wiring and labour costs, minimise the number of failure points and shorten the response time. For applications with many different varieties of process signals in the same location and there is room for future expansion then modular Ethernet remote I/O will be ideal.

Industrial Networking

Amplicon supplies a wide range of industrial networking solutions that deliver ideal network response time and impressive network resilience, security and reliability to industrial networking infrastructures. Amplicon's Industrial network products guarantee a high return on investment, low total cost of ownership, efficient productivity and easier deployment and implementation of an industrial network.

Panel Instrumentation

Amplicon has an extensive range of panel instrumentation, including HMI/panel PCs, digital panel meters, bargraph meters, large displays and PID controllers; combined with a proven track record in supplying panel instrumentation products to industries such as chemical, pharmaceutical, food & beverage, refineries and transportation for use in process control applications.

Amplicon's Measurement & Control division are specialists in the design of industrial process control solutions, so please contact one of our application engineers to discuss your applications.

Services

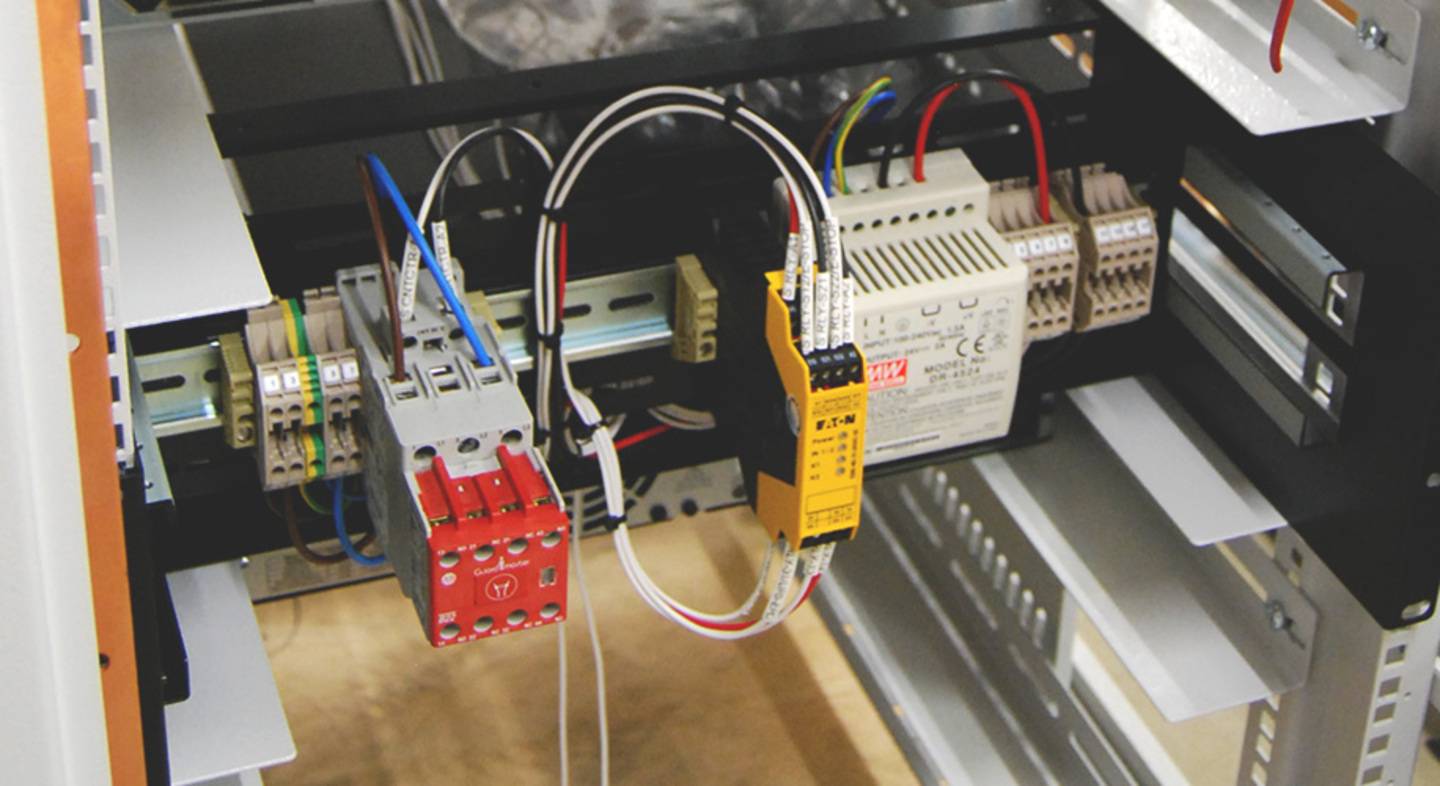

The Amplicon integration technicians have been supplying Process control systems for over 50 years; our team of experienced Process control specialists are able to support you with product knowledge, system design and customisation as well as post sales technical advice.

Some of the customisation services we offer to our process control customers include:

Project management & integration

The Amplicon process control division can manage your project from concept to completion; our engineering team are able to take the pain out of building any panel or cabinet allowing you to concentrate on your core abilities.

Procurement Services

An Amplicon customer can benefit from the competitive pricing that can only be offered by a manufacturer and Tier 1 distributor. As an additional service our purchasing team will source any third party hardware. Our engineering team will then integrate this into your solution, enabling you to benefit from the simplification of your supply chain in placing one order with a secure and trusted supplier.

Network Commissioning

Amplicon have a wide range of services to support our extensive portfolio of data communications products.

Over many years Amplicon has gained first-hand knowledge of customer's requirements, and it is this experience that gives us the ability to provide a comprehensive range of services for data communication products and systems. This includes network architecture design, network consultancy and complementary network services.

Markets & Applications

Whether you work in Oil & Gas, Food & Beverage, Water/Waste water, Power Utility, Factory Automation, Transportation or any other industrial market, Amplicon can provide a customised Process control solution to meet the precise requirements of your project.

Below you can find a selection of Amplicon Process Control projects across a wide range of markets: